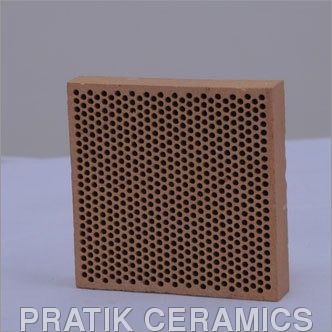

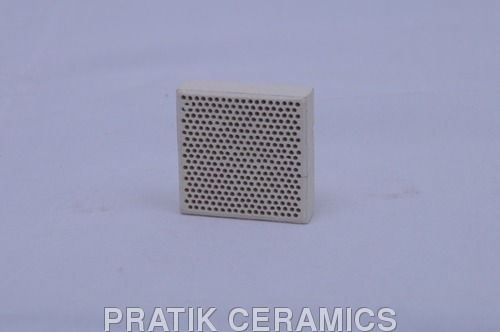

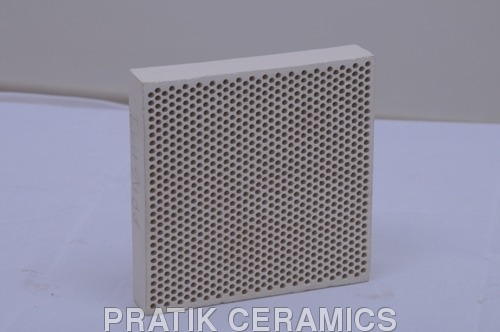

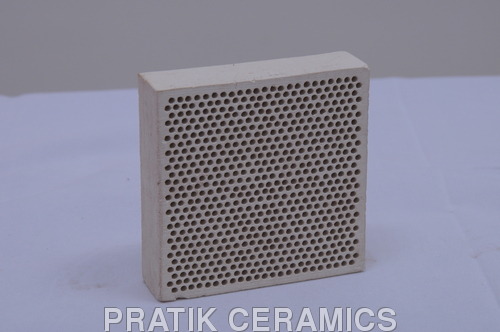

Foundry ceramic filter

Foundry ceramic filter Specification

- Product Type

- Ceramic Parts

- Ceramic Type

- Alumina Ceramic

- Size

- 5-10 Inch

- Material

- Alumina Ceramic

- Weight

- 15 Kilograms (kg)

- Length

- 200 Millimeter (mm)

- Color

- White

- Application

- Metal filtration in foundry industry

- Temperature Resistance

- Up to 1500°C

- Porosity

- High

- Shape

- Rectangular/Square

Foundry ceramic filter Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 15-20 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Carton and Corrugated Box.

- Main Domestic Market

- Gujarat

About Foundry ceramic filter

| Ceramic Foundry Filters | |

| Brand | Pratik |

| Origin Country | Thangadh, Gujarat, India |

| Matrial | White Refractory |

| Temp. | 900 to 1000c |

| Size | 100 X 100 X 21 |

| Application | Iron and Steel Foundry |

| Minimum Order Quantity | 1000 psc |

Exceptional Filtration Efficiency

Our alumina ceramic filters feature high porosity, enabling superior removal of inclusions and impurities from molten metal. They improve the quality and mechanical properties of cast products, making them a critical component for modern foundry operations.

Tailored for Demanding Environments

With robust temperature resistance up to 1500C, these filters are engineered to endure the harsh conditions of industrial metal casting. Their rectangular and square designs ensure versatile installation and compatibility with a range of casting setups.

Trusted Supplier from India

As an established exporter, manufacturer, and supplier, we deliver ceramic filters nationwide and globally. Our commitment to quality and customer satisfaction ensures you receive reliable products that meet indexing and production standards across the foundry sector.

FAQs of Foundry ceramic filter:

Q: How are alumina ceramic filters used in the metal filtration process within foundries?

A: Alumina ceramic filters are typically placed in the molten metal stream to capture impurities, resulting in cleaner metal output. Their high porosity and temperature resistance allow them to filter effectively during the casting process.Q: What are the benefits of using rectangular or square ceramic filters in foundry applications?

A: Rectangular and square shapes offer easy handling, installation, and maximize filtration area coverage. This design ensures efficient impurity removal, leading to higher quality castings and reduced defect rates.Q: When should foundries choose high porosity alumina ceramic filters for their operations?

A: High porosity alumina ceramic filters are ideal when castings require excellent surface finish and defect minimization. They are best suited for operations involving steel, iron, or non-ferrous metal casting at temperatures up to 1500C.Q: Where can these foundry ceramic filters be sourced for export or supply in India?

A: We are a leading exporter, manufacturer, and supplier based in India, catering to both domestic and international markets. Filters can be ordered directly via our sales channels or through authorized distributors.Q: What is the process for installing a ceramic filter in a foundry system?

A: Installation involves positioning the filter in the mold gating system where molten metal flows. The filters size and shape are selected to match the mold design, ensuring optimal filtration and minimal disruption to casting operations.Q: What advantages does alumina ceramic material provide for high-temperature metal filtration?

A: Alumina ceramic offers excellent thermal stability, chemical inertness, and high mechanical strength, making it ideal for maintaining filtration integrity under extreme casting temperatures and preventing contamination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ceramic Filters Category

Extruded Ceramic Filters

Price 50 INR

Minimum Order Quantity : 1000 Pieces

Product Type : Filter

Length : 200 Millimeter (mm)

Weight : 15 Kilograms (kg)

Material : Alumina Ceramic

Ceramic Water Filters

Price 50 INR

Minimum Order Quantity : 1000 Pieces

Product Type : Ceramic Parts

Length : 200 Millimeter (mm)

Weight : 15 Kilograms (kg)

Material : Alumina Ceramic

Ceramic Foundry Filters

Price 50 INR

Minimum Order Quantity : 1000 Pieces

Product Type : Ceramic Parts

Length : 200 Millimeter (mm)

Weight : 15 Kilograms (kg)

Material : Alumina Ceramic

Ceramic Foundry Filter

Price 50 INR

Minimum Order Quantity : 1000 Pieces

Product Type : Filter

Length : 200 Millimeter (mm)

Weight : 15 Kilograms (kg)

Material : Alumina Ceramic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS